Products Category

News Center

Contact Us

News

Difference between HF press and Induction heating press |

| Author:CHANCS Date:10/1/2016 5:05:58 AM |

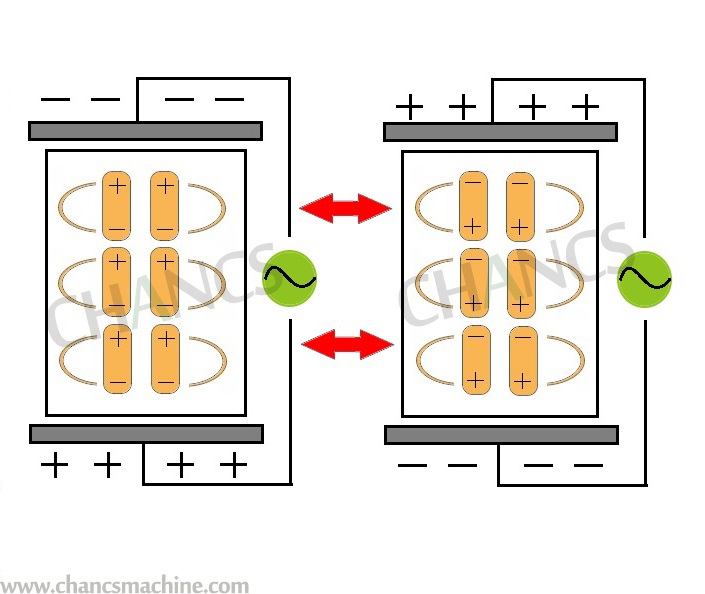

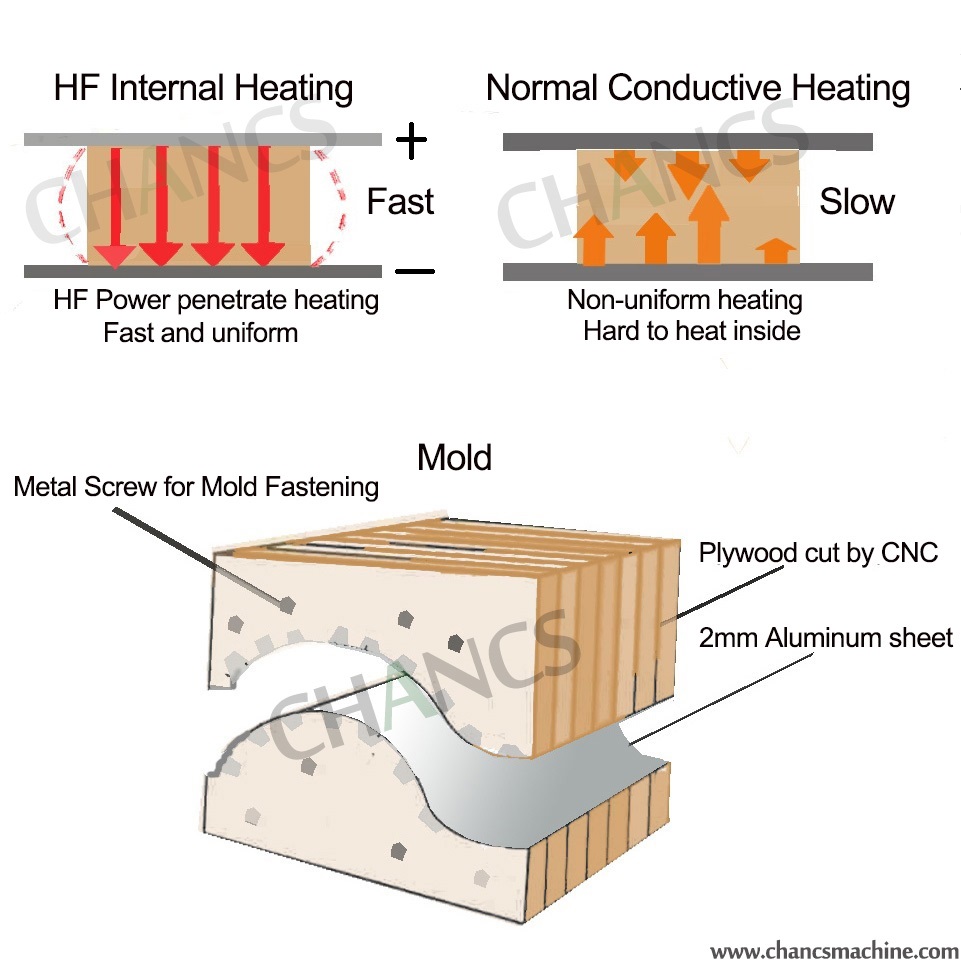

For plywood bending, there are two kinds of bending methods: Cold pressing and hot pressing. Vacuum bag and cold hydraulic press belong to cold pressing. Now we focus on hot pressing: Induction heating and high frequency heating. 1. Heating time and efficiency Induction heating includs hot steam, hot water and resister heating. Induction heating pre-heat mold (aluminum) first,transfering heating from mold to workpiece step by step then cure the adhensive from outside in. It not only heats glue but also heat whole workpiece at the same time. In this way, heating power costs more and curing time increased. High frequency heating: High frequency generator can form electromagnetic field between two layers of thin aluminum sheet called electrode. In this field, hf power can drive water molecules running and heating by friction. HF heating is fast and selective (only glue line get heated by molecules friction) thus can produce a variety of components cost-less and in high efficiency. Throughput is the top advantage of high frequency plywood bending press. 2. Mold making and costs Both heating methods needs mold. But their mold making is totally different. Induction mold: Needs large quantity of metal (mostly with aluminum), processing by CNC machine. It needs professional metal processing factory support, or woodworking factory cannot produce conveniently. High frequency press mold needs three main parts: plywood, 1-2mm thick aluminum sheet, and long screws. Plywood also needs cut by CNC one by one, then fasten with long screws. Finally attach thin aluminum sheet on the surface. Every woodworking manfuacturer can design and produce easily and conveniently.   |

Home |

About Us |

Products |

Videos |

News |

Successful Case |

FAQ |

Contact Us |

SiteMap

Copyright (c) CHANCS MACHINE All Rights Reserved

Copyright (c) CHANCS MACHINE All Rights Reserved