Products Category

News Center

Contact Us

News

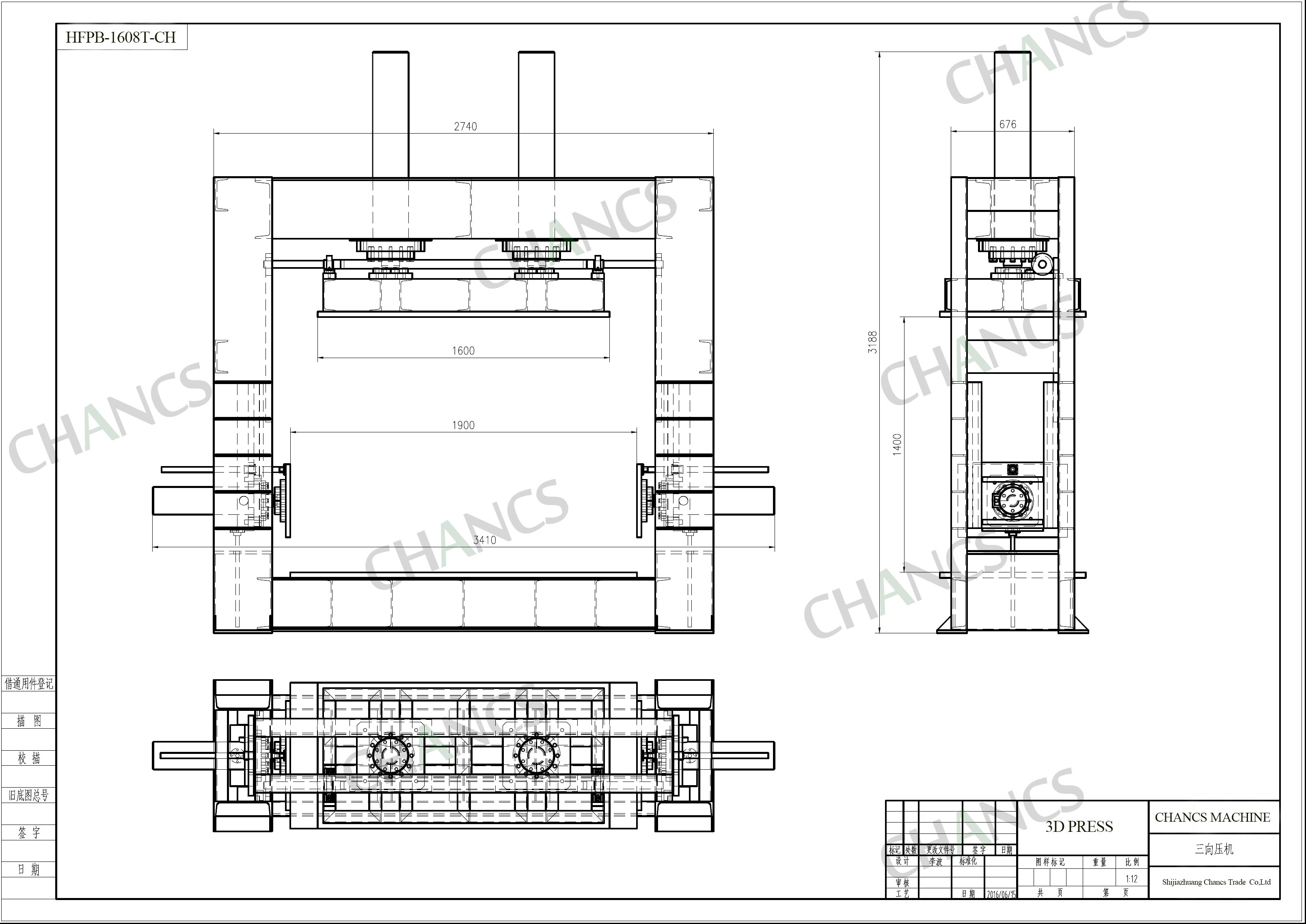

3D HF Plywood Bending Press Ready For Shipping |

| Author: Date:8/18/2017 11:36:05 PM |

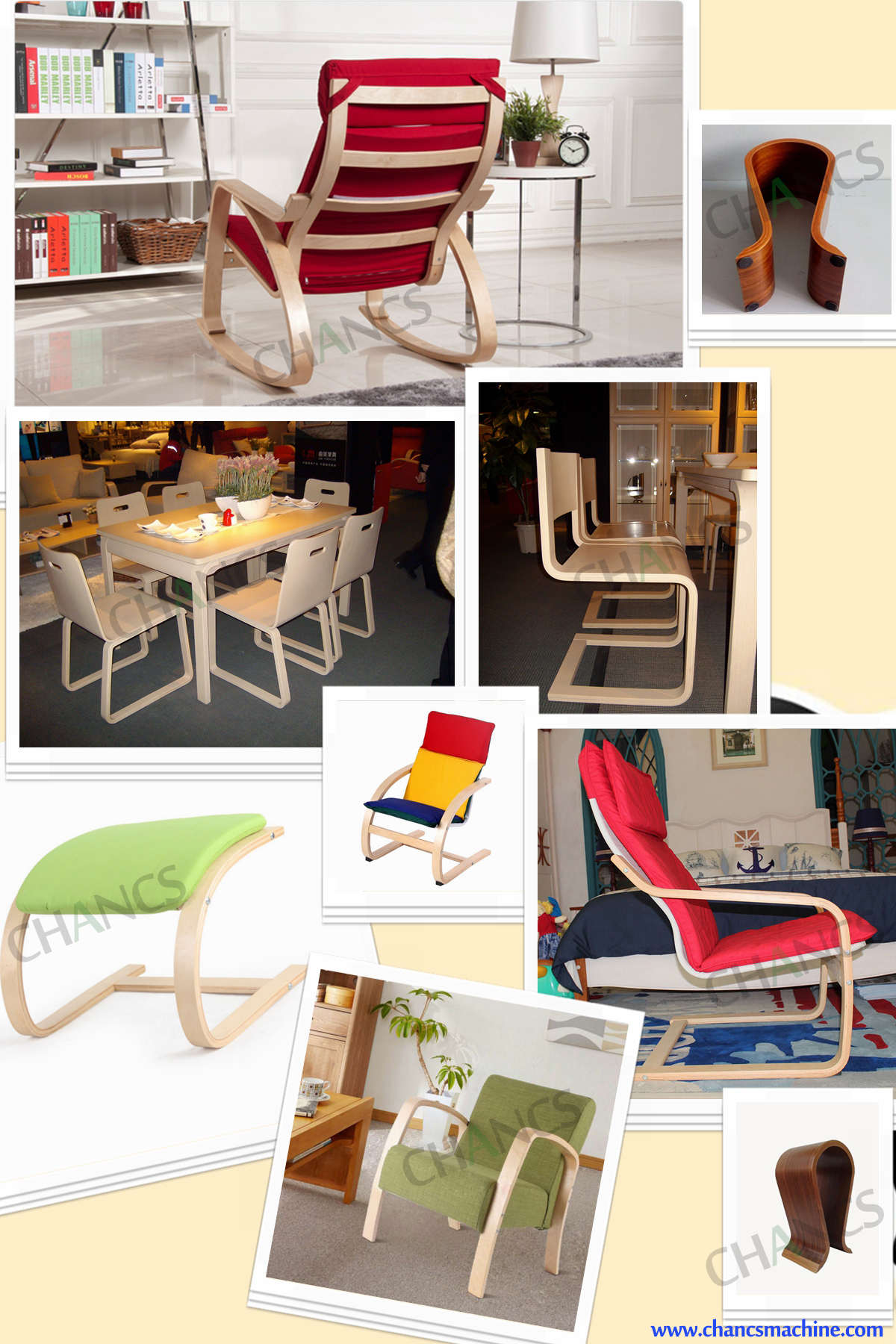

Two sets 3D HF Plywood Bending Press finsihed production and are ready for shipment. 3D HF press is also named 3 direction pressure High Frequency Plywood bending press. There are 4 main parts on the machine. 1. High frequency generator Also called HF generator. Power on 3 phase 380V, It can generate electromanetic field and let glue/ water molecules get heated by friction. The heating efficiency is higher and effects is more uniform. Can help customer save more power and imporve the efficiency speed.There are two outputs on high frequency generator(Left output and right output). Then can connect two sets of press. 2. 3D hydraulic press Hydraulic press equips top cylinder and side cylinders. Then can give pressure on different direction. Two of sides cylinders can also move up and down accordingly.Then can help customer produce differen shapes and size curved plywood components. 3. Hydraulic station There are valves and control parts on Hydraulic station. It is used to hold hydraulic oil and supply pressure. In order to save customer costs and imporve the efficiency, we design two sets hydraulic press share one hydraulic station. 4. Mold Mold can be made by metal or by plywood. Metal mold is more durable, but the costs is high. End customer cannot produce metal mold easily. But for plywood mold, it will be more convenient and costs saving. Customer can design different shape of mold then cut the plywood one by one via CNC. Then use long screw to hold cutting plywood together. Add 1.5-2mm thick aluninum sheet on the surface. The mold will be finished.     |

Home |

About Us |

Products |

Videos |

News |

Successful Case |

FAQ |

Contact Us |

SiteMap

Copyright (c) CHANCS MACHINE All Rights Reserved

Copyright (c) CHANCS MACHINE All Rights Reserved