High Frequency Plywood Bending Press |

|||||||||||||||||||||||||||||||||||||||||||||||||

|

|||||||||||||||||||||||||||||||||||||||||||||||||

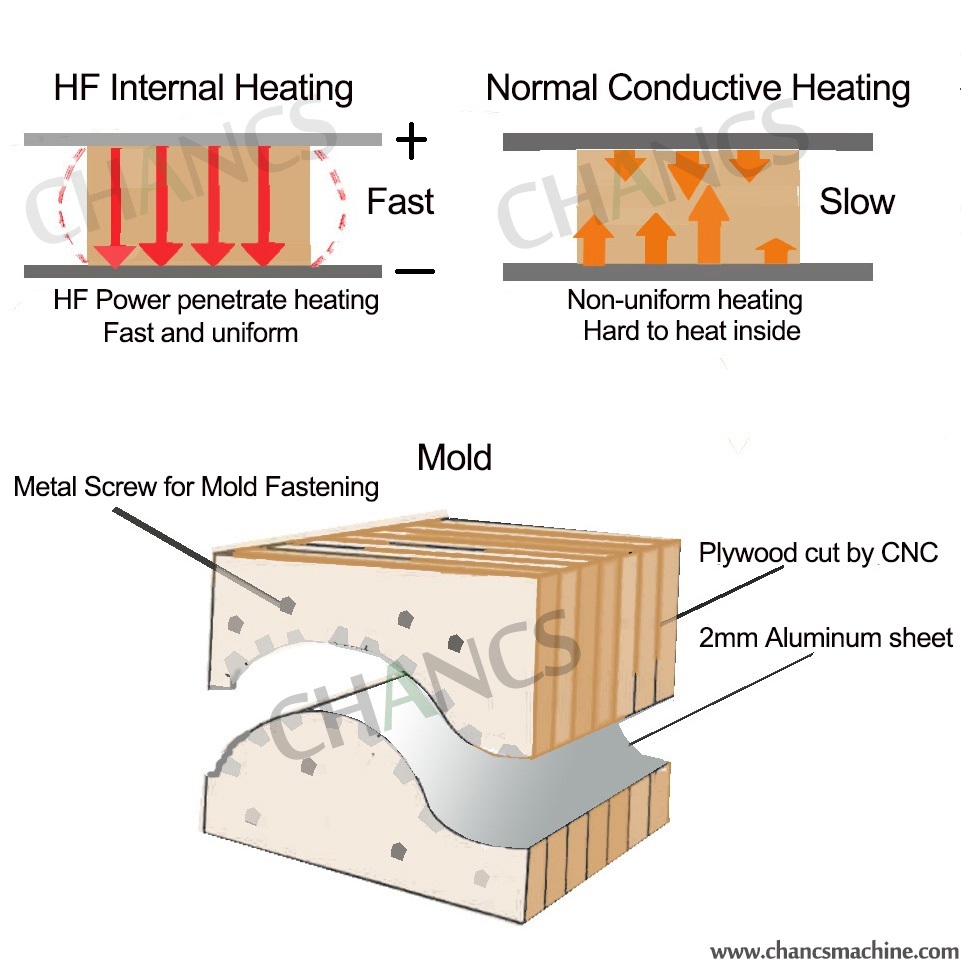

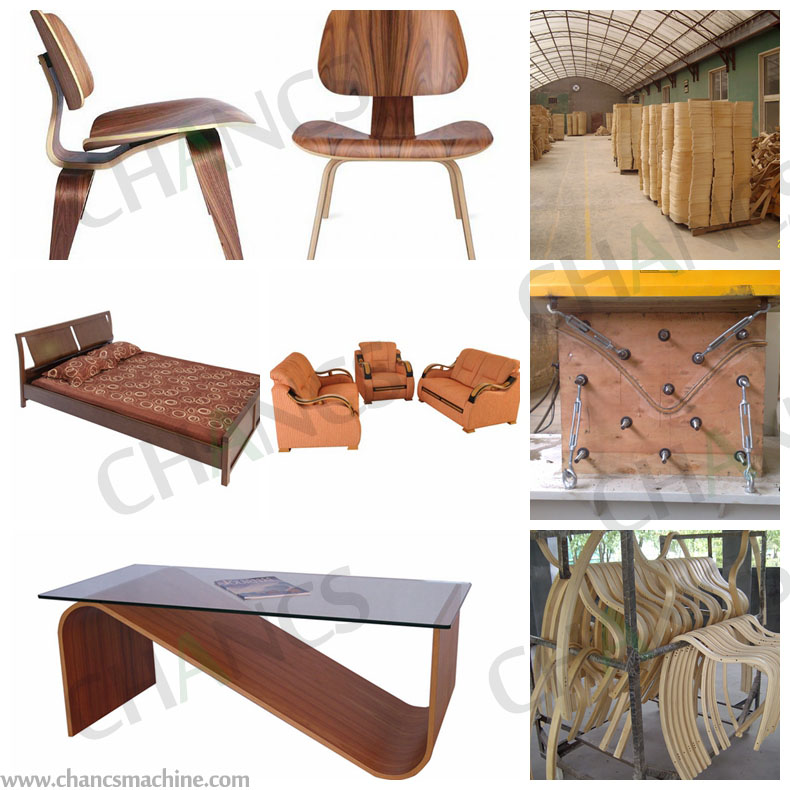

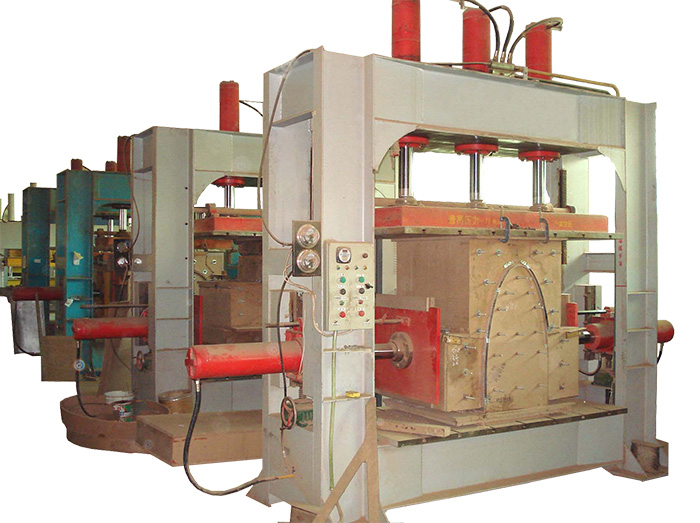

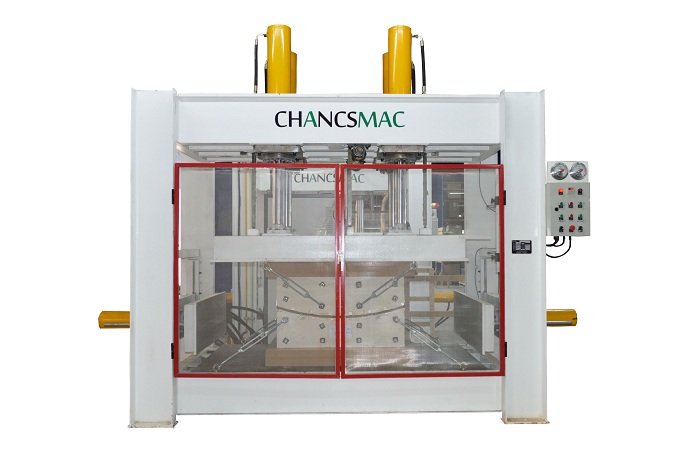

Working processure MDF bending Plywood bending 1. Introduction: High frequency plywood bending press can be used to produce a variety of plywood components in office furniture, school furniture, home furniture and children furniture, such as curved plywood chair seats and backs, sofa arm rest, TV stand, tea table, bed slats, baby bed, guitar rim, sound box etc. HF plywood bending press can also bend MDF and HDF into bed heads, cabinet door face, panel furniture etc. 2. Features of high frequency plywood bending press

|

|||||||||||||||||||||||||||||||||||||||||||||||||

|

←[Previous:] | ||||||||||||||||||||||||||||||||||||||||||||||||

| Related Products : |

|

|

|

Copyright (c) CHANCS MACHINE All Rights Reserved